Next-Generation Controller to Advance Scalable Viral Vector Manufacturing

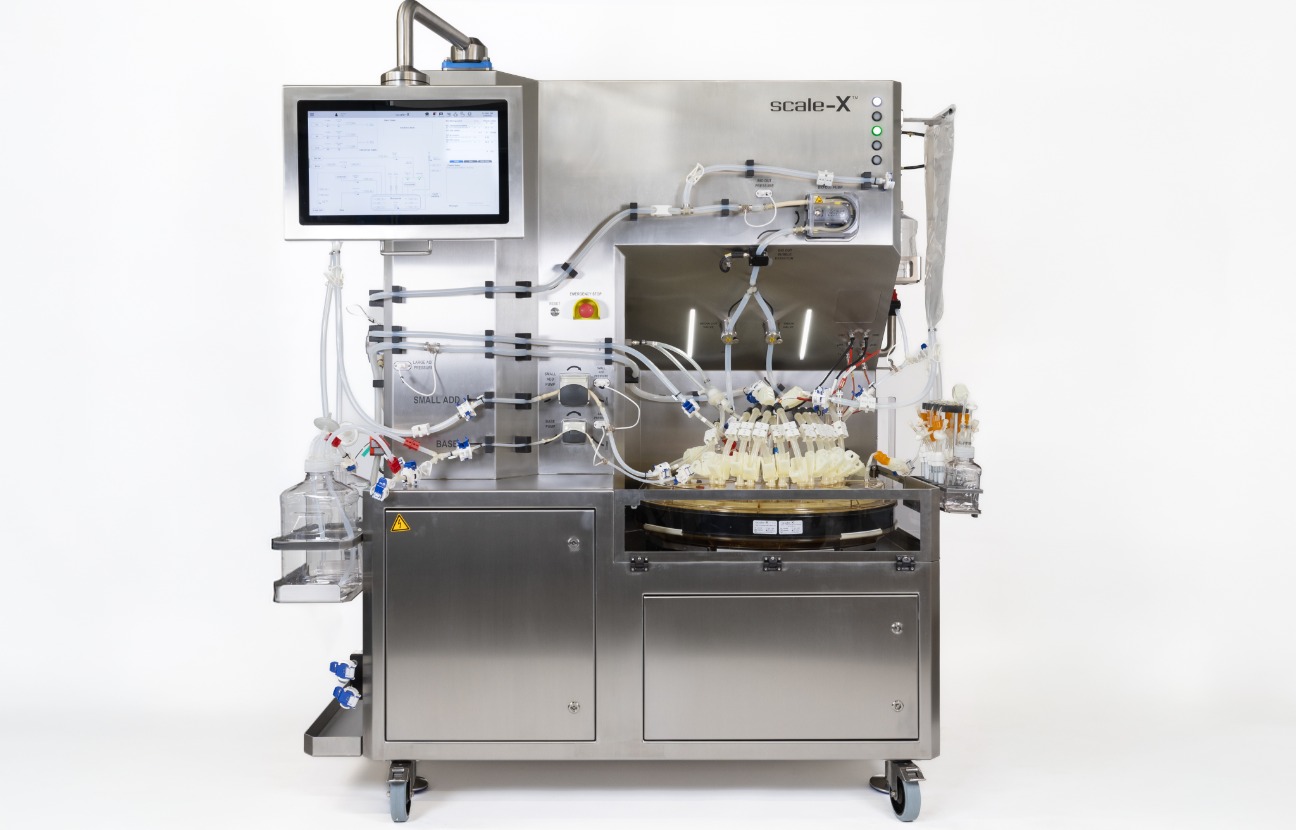

Univercells Technologies, a Donaldson Life Sciences business and global provider of innovative bioprocessing solutions, has launched the scale-X™ nitro controller, a significant new addition to its scale-X fixed-bed bioreactor platform. Designed to operate both the 200 and 600 m² versions of the scale-X nitro bioreactor, the controller further strengthens Univercells’ commitment to offering cost-effective, low-footprint, and scalable technologies for large-scale manufacturing of viral vectors and advanced therapies.

The scale-X™ nitro controller is tailored for rapid scalability—from R&D to full commercial production in just eight months—meeting the needs of manufacturers seeking flexible and integrated GMP-compliant platforms. As Thomas Robert, PhD, Senior Innovation & Product Manager at Univercells Technologies, explained in an exclusive interview with MoveTheNeedle.news, “Customers need increased flexibility, and enhanced integration within existing manufacturing environments. The nitro controller responds to these needs by offering a future-proof platform designed with the end-user in mind.”

A Mission-Driven Approach to Biomanufacturing

Univercells Technologies operates from a clear and ambitious mission: to make biologics more accessible by removing traditional cost and scale barriers in manufacturing. Formed in 2020 as a spinout from Belgian biotechnology group Univercells, the company now functions as part of the Donaldson Life Sciences portfolio—leveraging synergies across a group of innovation-focused businesses including Isolere Bio, Purilogics, and Solaris Biotech.

“Our approach is unique in that we design solutions that are deliberately compact, scalable, and cost-efficient, without compromising on quality and performance,” said Robert. “We challenge the status quo of large, complex infrastructures by offering technologies that reduce facility footprint, operational complexity, and cost of goods.”

That mindset is particularly timely as the cell and gene therapy sector continues to evolve—and face capacity and cost pressures. Univercells Technologies is well-known for its scale-X™ bioreactor platform, which enables adherent cell culture in a fixed-bed format with a high surface-area-to-volume ratio. The design supports high-yield production of viral vectors, vaccines, oncolytic viruses, and exosome-based therapies, among other biologics.

Designed for Modern Manufacturing Needs

The new nitro controller is built to maximise flexibility while minimising footprint and cost—a compelling combination for gene therapy developers, CDMOs, and vaccine manufacturers looking to modernise or scale up operations. “It particularly addresses the needs of gene therapy and vaccine manufacturers (direct or contract) that require a flexible, robust upstream solution that can seamlessly integrate in any manufacturing environment,” Robert said. “Organizations looking to modernize their upstream production based on adherent cell lines may find it a very attractive solution to drastically reduce manufacturing footprint and overall cost-of-goods.”

With its plug-and-produce design, the controller enables fast installation and ease of use, key attributes for agile biomanufacturing environments. Combined with the scale-X nitro bioreactor, the system offers a streamlined, next-gen solution for commercial-scale viral vector production—while reducing capital and operating expenses.

A Platform that Evolves with its Users

The nitro controller is the third product launch by Univercells Technologies in the past year, signalling the company’s momentum and ongoing investment in expanding its scale-X ecosystem. That ecosystem is shaped not just by internal innovation but also by customer partnerships and deep R&D collaboration.

“This includes possible product improvements based on the feedback of our users, but we’re also very driven by R&D and application development,” Robert said. “By generating data, knowledge, and protocols we strive to better support our customers through real partnerships.”

Now under the Donaldson Life Sciences umbrella, Univercells Technologies is well-positioned to integrate upstream and downstream solutions for biologics manufacturing. By combining its fixed-bed expertise with new purification, automation, and process control capabilities from sister companies, the firm is steadily building a modular, interoperable bioprocessing portfolio that aligns with the future of advanced therapies.

“These are exciting times ahead as we strive to solve the challenges in this space,” said Robert.