How Robotics Are Revolutionizing Vertical Farming

Inside Opollo Farm by AutoStore and OnePointOne

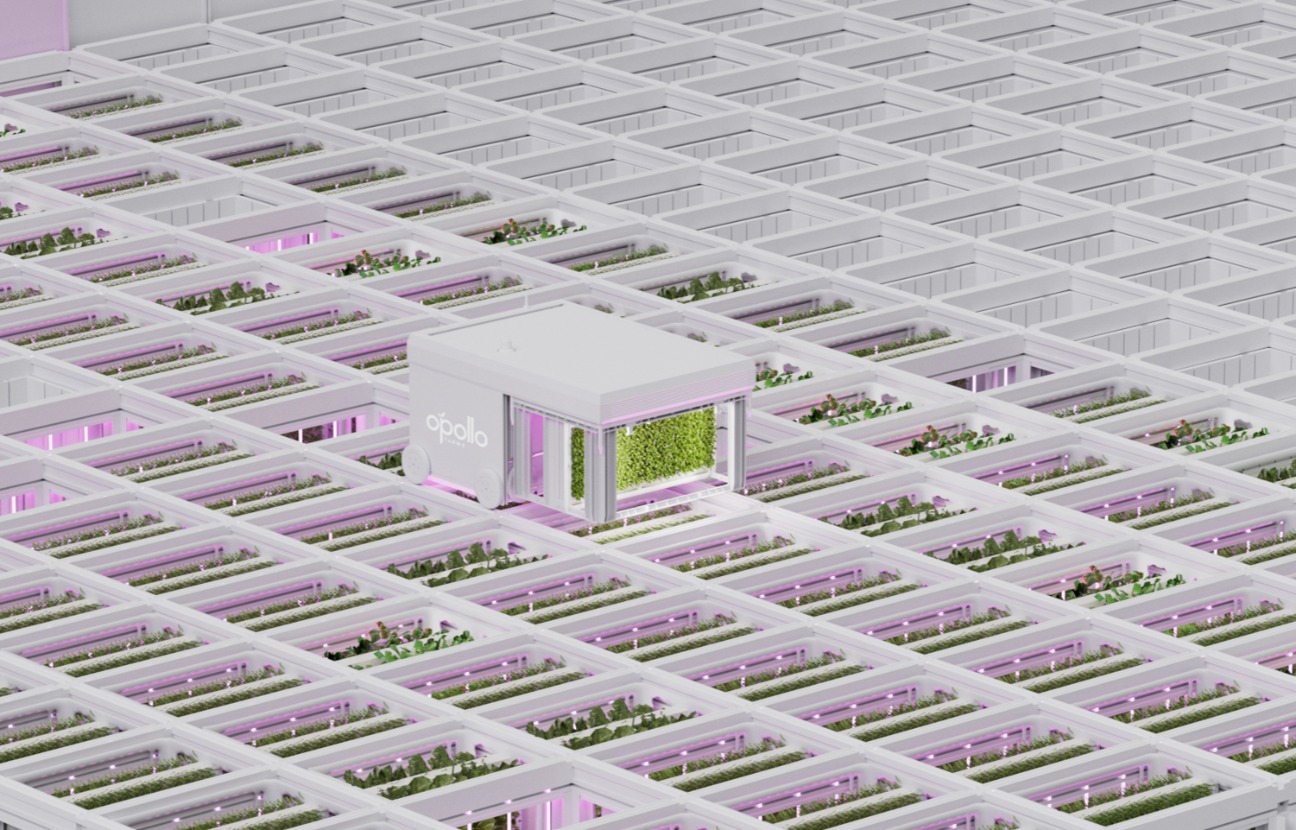

In the arid outskirts of Phoenix, Arizona, a technological marvel is reshaping the future of agriculture. Inside a high-tech warehouse, thousands of herbs and leafy greens flourish in robot-powered bins that glide silently through a towering, cube-like grid. This is Opollo Farm—the world’s first fully automated vertical farming system powered by AutoStore™.

Developed in partnership with controlled-environment agriculture innovator OnePointOne, Opollo Farm is a proof-of-concept that combines plant science and warehouse automation to deliver ultra-efficient food production. By using advanced robotics to nurture crops in a precision-controlled environment, the system cuts the time from seed to harvest to just 15 days—around half the time of conventional farming.

“Opollo Farm is a pioneering demonstration of how AutoStore’s high-throughput, ultra-reliable automation can transform industries beyond warehousing,” says Patrik Wallgren, Director of Product Strategy and Operations at AutoStore.

From Fulfillment to Farming: AutoStore’s New Frontier

Founded in Norway in 1996, AutoStore is known globally for its high-density, cube-based storage and order fulfillment systems. With over 1,600 installations across 60 countries, AutoStore’s solutions are a cornerstone of modern logistics for industries ranging from e-commerce and pharmaceuticals to grocery and healthcare.

What sets AutoStore apart is its modular cube storage system, which offers best-in-class space efficiency, ultra-high throughput, and a system uptime of 99.7%. These attributes have now found a new application: agriculture.

“Our system isn’t just about moving products. It’s about orchestrating smart infrastructure,” Wallgren notes.

The partnership with OnePointOne—a California-based agri-tech company specializing in vertical farming and plant science—was a natural evolution. Together, the two companies built Opollo Farm to tackle one of the world’s most pressing challenges: how to feed urban populations sustainably while minimizing environmental impact.

Precision Growing Meets Precision Movement

Unlike conventional farming, vertical farming takes place in stacked layers within a climate-controlled environment, using hydroponics and LED lighting to grow crops year-round with minimal land and water. What Opollo Farm adds to this equation is robotic intelligence.

At the heart of the operation is the AutoStore cube grid, repurposed to serve as a living growth chamber. Robots autonomously reposition plants based on their development stage, adjusting light, temperature, humidity, and nutrient levels with surgical precision.

“We didn’t reinvent the architecture—we adapted it,” says Wallgren. “Our engineers worked closely with OnePointOne to integrate plant movement, irrigation triggers, and harvesting workflows into our system. The result is a reliable, scalable, and highly adaptable farming platform.”

This level of automation not only increases efficiency but also reduces waste, water usage, and transportation emissions by growing food close to where it’s consumed.

Beyond Logistics: Enabling Sustainable Infrastructure

The success of Opollo Farm signals a broader shift in AutoStore’s vision—moving from logistics infrastructure to multi-industry robotics integration. The company is already piloting solutions in grocery fulfillment, temperature-sensitive storage, and now, urban agriculture.

AutoStore is also investing in AI-driven technologies like CarouselAI™, its next-generation robotic picking system, aimed at further boosting performance and adaptability across sectors.

“We’re not pivoting—we’re evolving,” Wallgren explains. “The future of robotics is agile, scalable, and deeply integrated into the fabric of modern life. That’s where AutoStore is headed—moving things forward.”

Why It Matters

As cities grow and climate volatility threatens traditional agriculture, resilient food systems are more critical than ever. Opollo Farm offers a glimpse into how automation and agriculture can converge to meet that challenge. It's not just about speeding up harvests; it's about reinventing how food is produced, distributed, and consumed in the 21st century.

With innovations like this, AutoStore is helping redefine what’s possible—not just in warehouses, but in the fields of the future.